Reverse Fmea Example PPT FMEA PowerPoint Presentation ID193914

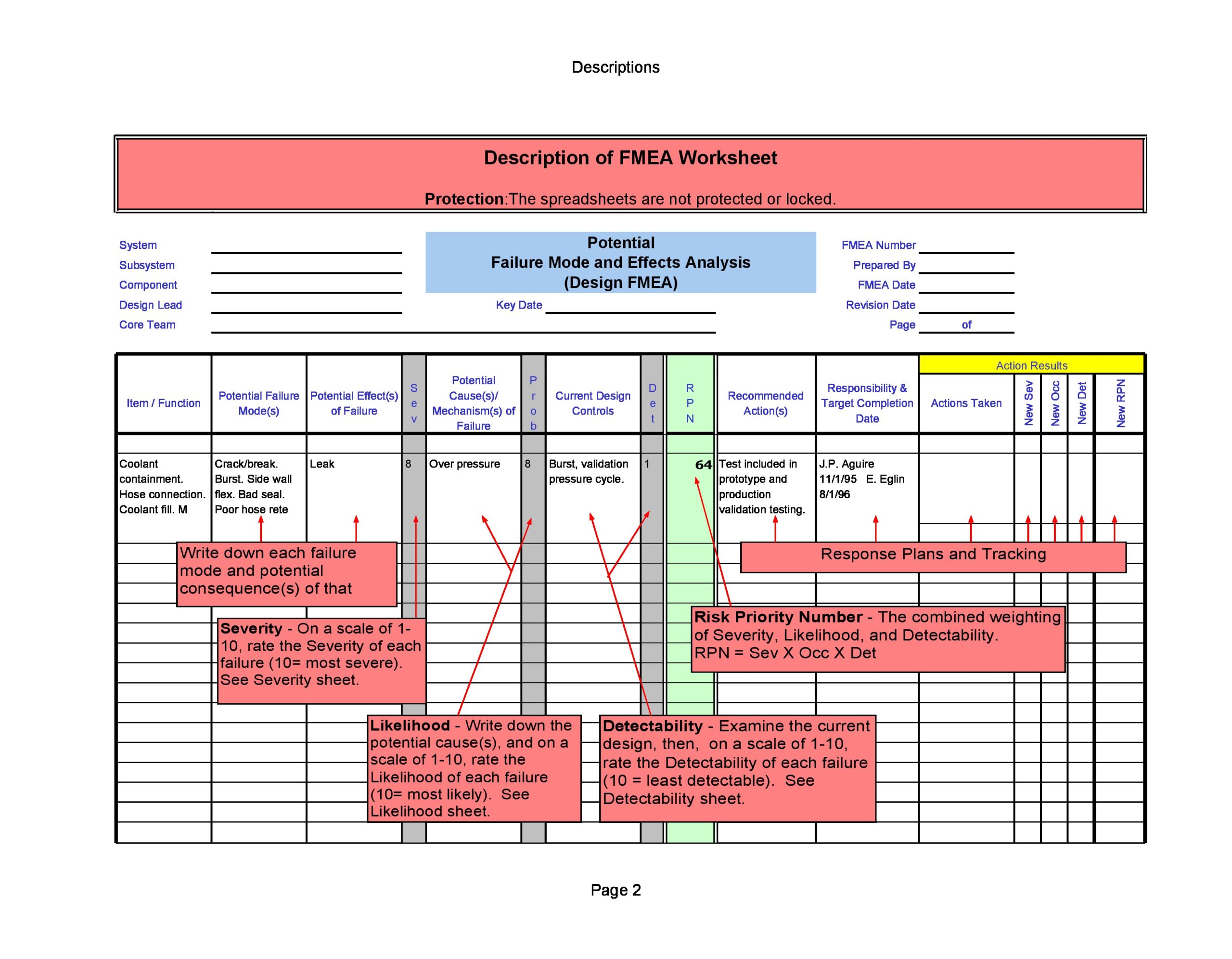

4 Stages of Reverse FMEA Key: A) Metrics B) Scrap C) Recommended Actions D) Special Characteristics E) Risk Prioritization Planning PERFORMED PRIOR TO THE REVERSE FMEA A. Line's metrics and historical performance B. Top 3 scrap issues for the line C. Future activities that will affect this line

Process FMEA Template, Use Cases, and Examples

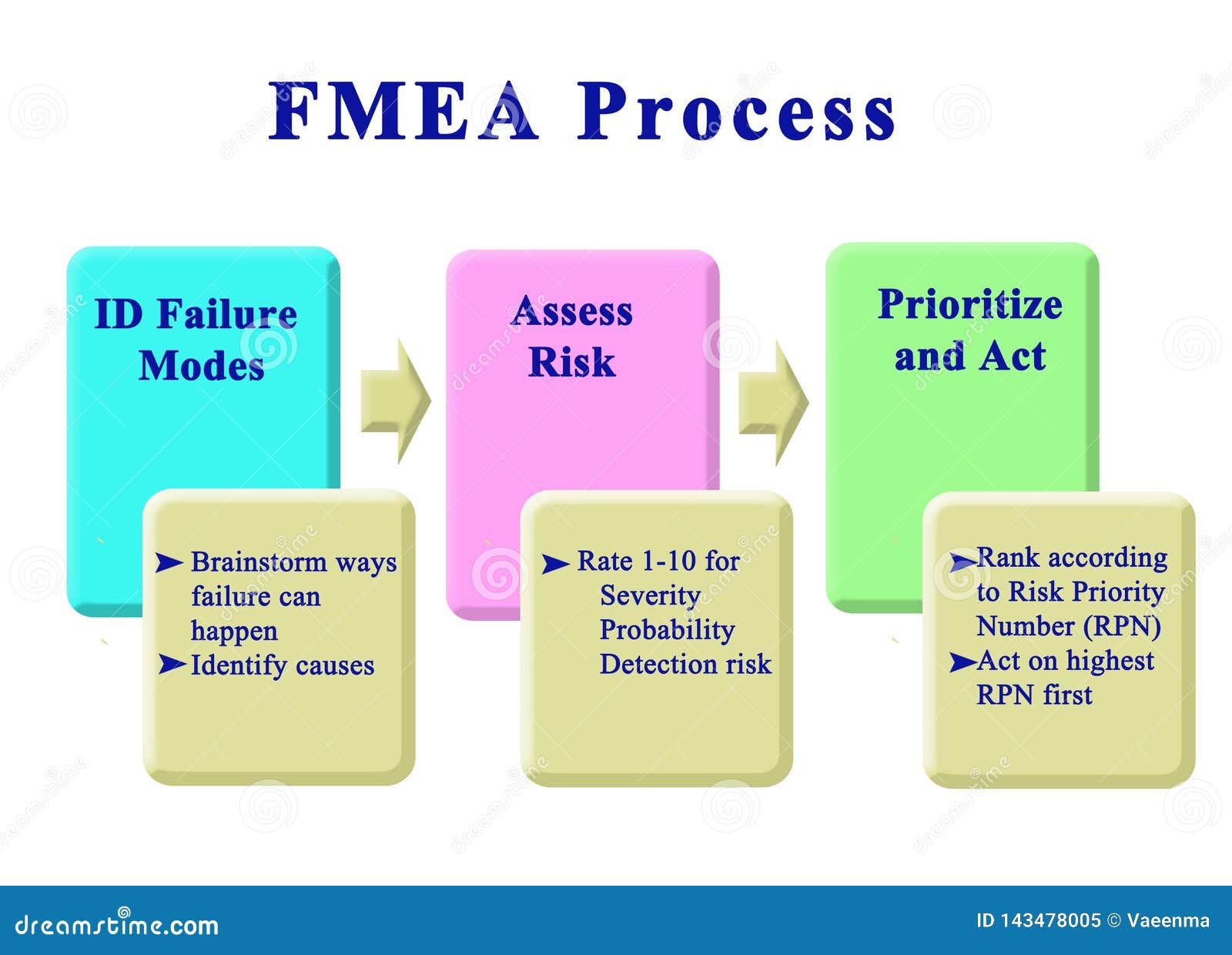

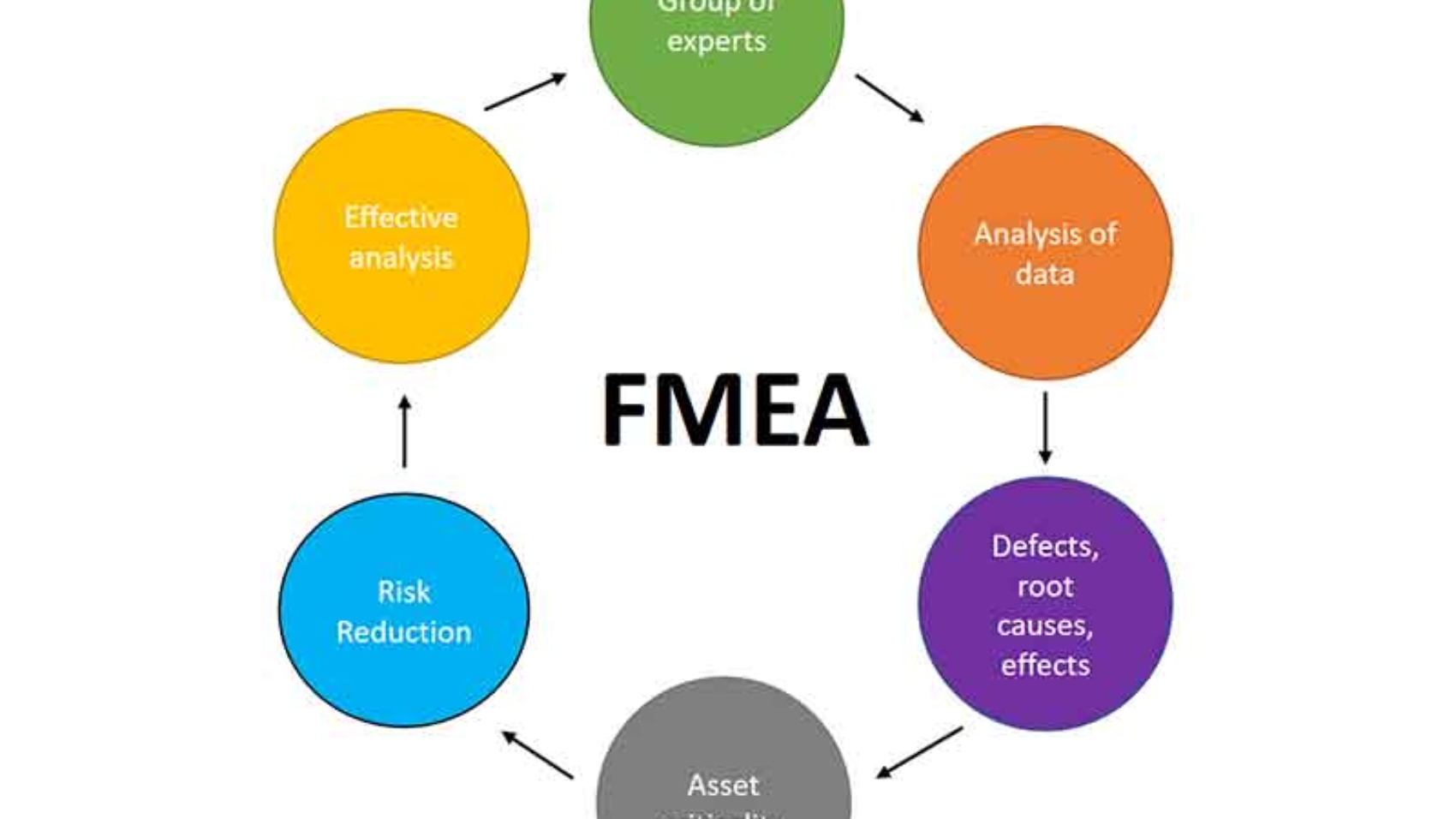

Reverse FMEA is a structured process of continuous improvement that aims to ensure the permanent updating and progress of an FMEA (Failure Mode and Effect Analysis) study. This risk assessment method is based on reality and not predictive reliability. The recording is available for you to watch, or find it on our podcast.

Reverse FMEA

On Dec. 7, 2021, Ford Motor Co. updated its IATF 16949—"Customer specific requirements" (CSR), which requires the use of reverse FMEAs (RFMEA) on new equipment ("tooling"). The first sentence of the reverse FMEA requirement reads: "Organizations are required to have a process in place that ensures all new launches complete an RFMEA.

Steps in FMEA Process Stock Photo Alamy

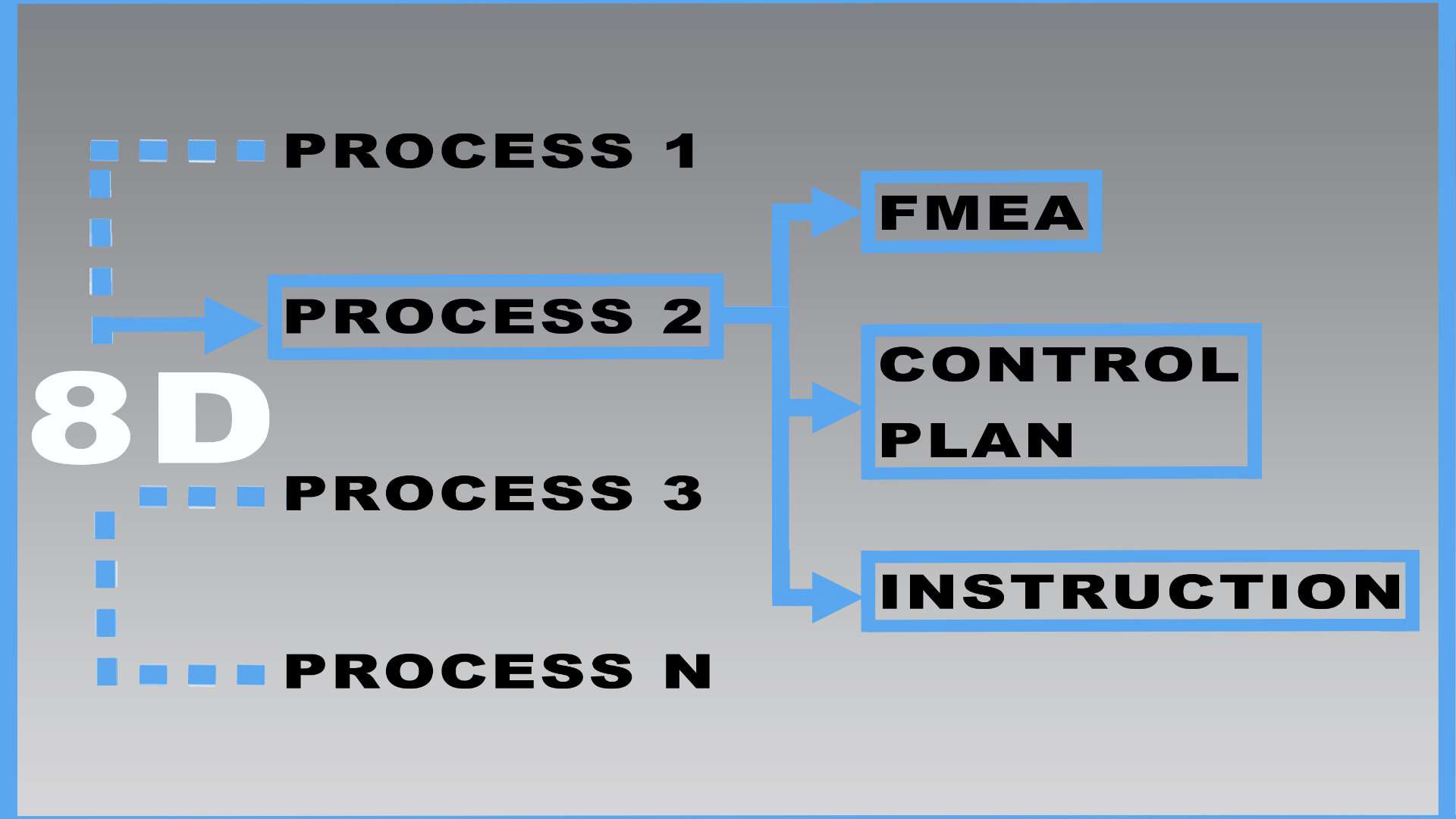

Course Duration: 2 Days - 8 Hours/day. This two-day, hands-on seminar is intended to offer insight into, and hands-on experience with, the linkages between various aspects of the Advanced Product Quality Planning (APQP) process. Specifically, the development and linkage of the PFMEA to the Reverse FMEA. RFMEAs are performed after production.

The traditional FMEA procedure Download Scientific Diagram

The purpose of Reverse FMEA is to validate the assumptions made when the FMEA was created and see if they still hold true. In this process, the observations from the Reverse FMEA are incorporated into the existing Process FMEA and further processed there. This means that new defects and new causes of defects may be discovered, which may also.

Process FMEA Template, Use Cases, and Examples

Reverse FMEA is a structured process of continuous improvement that aims to ensure the permanent updating and progress of an FMEA (Failure Mode and Effect Analysis) study. This risk assessment method is based on reality and not predictive reliability.

Steps in FMEA Process stock illustration. Illustration of happen

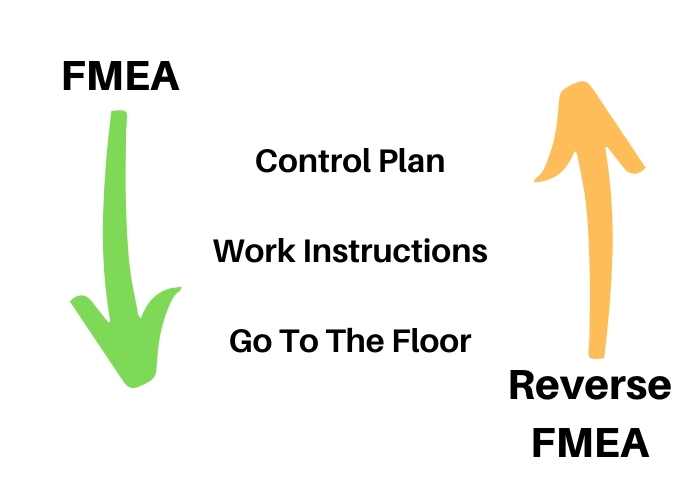

What is Reverse FMEA? Reverse FMEA in its simplest form is a bottom-up validation. When you create an FMEA you're starting from an ideal top-down perspective. Reverse Process FMEA Fundamentals - Live Virtual Seminar

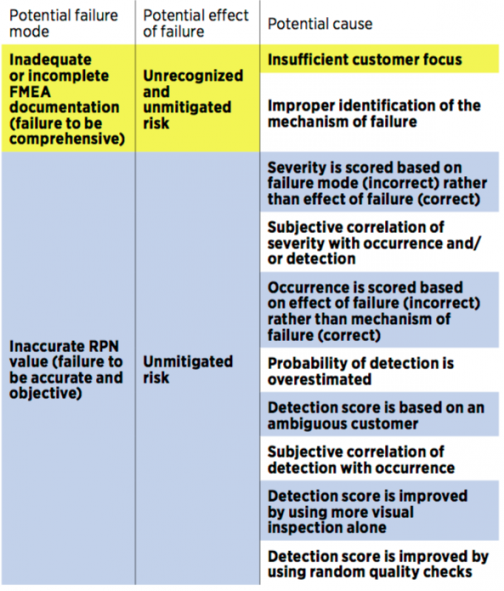

Reverse Evaluation of Failure Mode and Effects Analysis Model A New

Have you ever heard of Reverse FMEA? It's a proactive approach to risk management that allows you to identify potential failure risks before they occur. In t.

Reverse Fmea Example PPT FMEA PowerPoint Presentation ID193914

Reverse FMEA in its simplest form is a bottom-up validation. When you create an FMEA you're starting from an ideal top-down perspective because the FMEA sets the cadence for the control.

Reverse Fmea Example PPT FMEA PowerPoint Presentation ID193914

Reverse-FMEA is the method/tool to review the PFMEA using on-site or shop floor observation. In this method, the organizations should check their existing FMEA with actual shop floor process. And improve it by identifying new failures and their corrective and preventive actions. Reverse FMEA method and Steps

Failure Mode and Effects Analysis (FMEA) Overview Jama Software

Reverse FMEA is an approach to applying the proven FMEA risk management and mitigation processes in "reverse", as you may expect! This technique was initially adopted in the automotive OEM space - notably by Ford.. RFMEAs are beneficial for any business looking to gain additional insight into their risk management procedures once the.

Reverse FMEA Webinar YouTube

Reverse FMEA flips the perspective by starting with the desired outcome or performance goal and working backward to identify the potential causes that could hinder achieving that goal. This novel technique offers a fresh approach to risk analysis and problem-solving, enabling organizations to identify and mitigate potential obstacles to success.

Reverse Fmea Example PPT FMEA PowerPoint Presentation ID193914

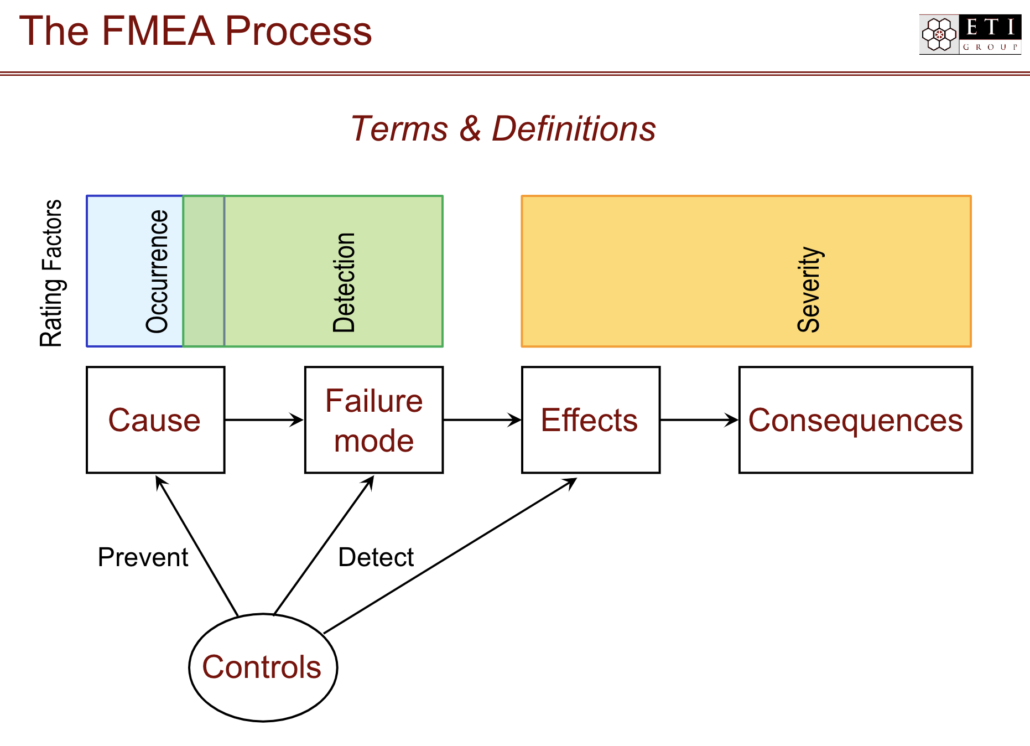

In basic terms, the Reverse FMEA (always centered on the PFMEA) is a focused review of the operation, to access controls identified in the approved PFMEA and testing to verify the ranking assigned for the various prevention and detection controls.

FMEA Insights in Manufacturing Industry Cademix Institute of Technology

Reverse FMEA is a structured process of continuous improvement that aims to ensure the permanent updating and progress of an FMEA study. Therefore, it is a tool to support the application of FMEA.

Reverse Fmea Example PPT FMEA PowerPoint Presentation ID193914

3. There are no RFMEA experts. 4. Standardized tools to manage tooling risk exist in the automotive industry that negate the need for the RFMEA when used correctly. 5. There is a lack of understanding of how to properly use the available standardized tools to manage tooling risk. 6.

30 Useful FMEA Examples (Free Templates) TemplateArchive

Reverse FMEA (Failure Modes & Effects Analysis) is one of the most recent tools used for continuous improvement, which I personally consider a revolution in the field of risk management. Reverse FMEA is used to enhance the PFMEA, since it's based on on-site observation.